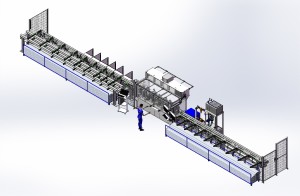

Full Immersion :

It concerns tubes & bars from diameter 6 up to 50mm to be controlled outline (already cut to length). These benches enable a full flaw detection (Full Body UT), with a rototranslation motion (RT – helicoidal movement), Phased Array sensors (PA) placed in a tank (Full Immersion). This combination guarantees a 100% coverage as well as a productivity corresponding to the tube producers need. As an option, a complete dimensional control (WT, OD, ID, excentricity…and so on) can be added on the same bench.

The reference flaw to be detected relies on customer specifications. Generally speaking, this FBUT-RT-PA Series aims at longitudinal & transversal flaws size: (Length x Wide x Depth) 1.5mm x 0.080mm x 0.050mm.

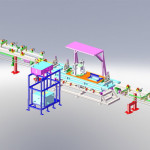

Local Immersion :

It concerns tubes & bars from diameter 10 up to 300mm to be controlled outline. These benches enable a full flaw detection (Full Body UT), with a rototranslation motion (RT – helicoidal movement), Phased Array sensors (PA) placed on an inferior tank (Local Immersion). This combination guarantees a 100% coverage as well as a productivity corresponding to the tube producers need. As an option, a complete dimensional control (WT, OD, ID…and so on) can be added on the same bench. The reference flaw to be detected relies on customer specifications. Generally speaking, this FBUT-RT-PA Series aims at longitudinal & transversal flaws size: (Length x Wide x Depth) 1.5mm x 0.080mm x 0.050mm or FBH up to 0.7mm

English

English