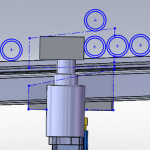

Feeding tables works using gravity. Tubes lay down against stops and are ejected by automation. Several kinds of ejection are available, depending on the context.

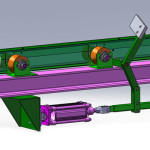

For example, double ejections are used after tube control (one side for tubes tested as good and one side for tubes rejected). Stops settings are necessary to adapt the system for the tube diameter range desired. Again, several technologies are available, from manual to fully automated systems.

In this case, operators are able to change all the settings for a new tube diameter from their workstation.

English

English